Fokozatok |

Brookfield viszkozitás 1% vagy 2% |

Nedvességtartalom |

Hamu tartalom |

Részecskeméret |

Ömlesztett sűrűség |

TDS letöltése |

|---|---|---|---|---|---|---|

HE30 |

1,500 - 2,500 |

≤6% |

≤5% |

98% átjáró 80 szem |

300-600 g/ml |

Letöltés |

HE60BE |

2,500 - 3,500 |

≤6% |

≤5% |

98% átjáró 80 szem |

300-600 g/ml |

Letöltés |

HE100BE |

3,500 - 5,000 |

≤6% |

≤5% |

98% átjáró 80 szem |

300-600 g/ml |

Letöltés |

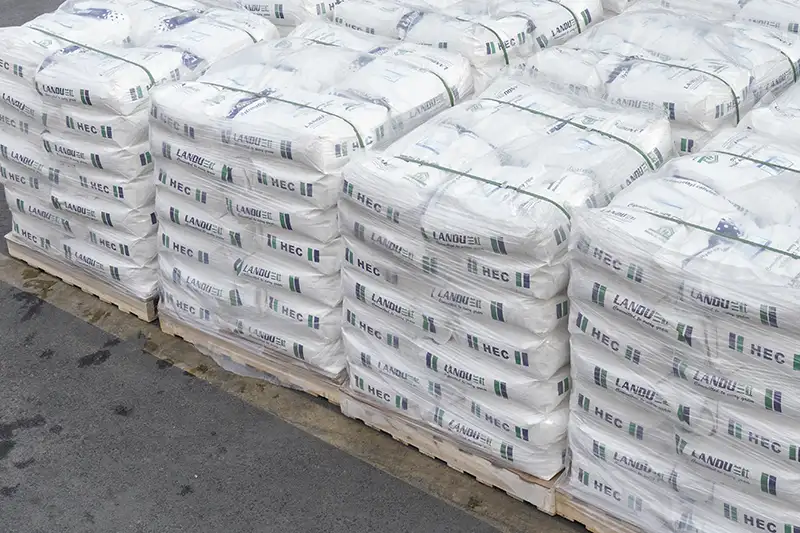

At LANDERCOLL, we offer comprehensive sampling services tailored for paint, coatings, and oil drilling applications. Our Hydroxyethyl Cellulose solutions are designed to enhance your products by providing superior thickening, water-preserving, and stabilization properties.

See for yourself – request a free sample!

| Weight: | 25kg/bag |

|---|---|

| Fast Delivery: | Shipment via Sea Freight |

| Add-Ons: | Customized Packaging |

LANDERCOLL has made significant investments in two dedicated laboratories aimed at developing innovative Cellulose Ether solutions. This focus on research and development underscores LANDERCOLL’s commitment to delivering high-quality, tailored solutions to improve product efficacy and versatility across many industries.

LANDERCOLL employs a comprehensive quality management system that includes rigorous testing at every stage of production, from raw material selection to final product evaluation. Utilizing state-of-the-art equipment, LANDERCOLL conducts a variety of tests, such as viscosity measurements, pH assessments, and microbial contamination checks, to guarantee that each batch meets the highest standards of quality and consistency.

LANDERCOLL has introduced Mechanical Vapor Recompression wastewater treatment technology. This facility allows for potential reuse or safe disposal of chemicals used in production. By integrating MVR into the production of Cellulose ethers, LANDERCOLL is able to achieve our Zero Liquid Discharge goals.

LANDERCOLL introduces cotton in cellulose ether production to enhance the quality of our products. This high-purity cellulose is then used to produce premium Cellulóz-éter and other polymer additives, ensuring optimal performance in various applications such as construction és pharmaceuticals.

Surface-treated HEC disperses in cold water without coagulating, but its dissolution rate is relatively slow, typically requiring about 30 minutes. Heating it or adjusting the pH to 8-10 can facilitate rapid dissolution.

When the solution temperature increases, the viscosity of HEC will decrease, and this process is reversible.

Yes, HEC solutions are compatible with most water-soluble polymers and can coexist with other cellulose ethers, starch and its derivatives, gelatin, and natural gums. HEC can also coexist with surfactants and salts, making it an excellent colloidal thickener for solutions containing high concentrations of electrolytes.

Keresse a LANDERCOLL-t még ma a részletes információkért és iránymutatásokért!