Introduction to HPMC in Tile Grout

Hydroxypropyl Methylcellulose (HPMC) is a water-soluble polymer derived from natural cellulose. It is widely used in construction materials due to its ability to improve water retention, workability, and adhesion. In tile grout, HPMC acts as a multifunctional additive, addressing common challenges such as cracking, efflorescence, and poor workability. Let’s dive into the seven properties that make HPMC essential for tile grout performance.

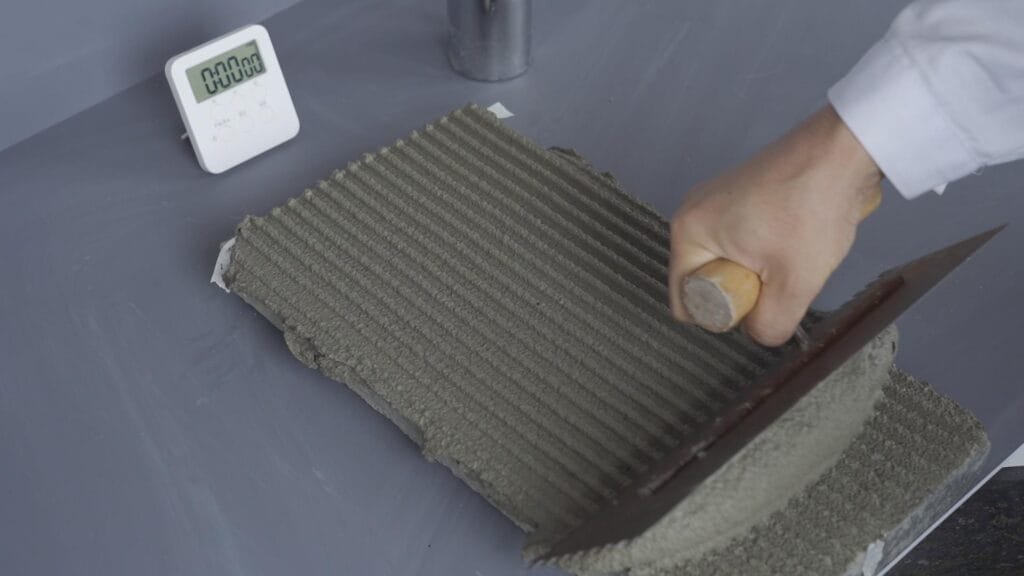

1. Enhanced Workability: Smooth Application, Faster Results

Why Workability Matters

Workability is crucial for ensuring that grout can be easily applied and spread evenly between tiles. Poor workability leads to clumping, uneven coverage, and increased labor costs.

How HPMC Improves Workability

Smooth Consistency: HPMC creates a creamy, non-sticky texture, making grout easier to spread.

Reduced Friction: Grout with HPMC doesn’t stick to tools or tiles, simplifying cleanup.

Faster Installation: Improved workability speeds up the application process, especially in large-scale projects.

Example: In floor-to-ceiling tile installations, HPMC ensures consistent grout application, reducing the time and effort required.

2. Extended Work Time: Superior Water Retention

Why Water Retention is Critical

Grout must remain workable long enough to allow for adjustments during installation. Premature drying can lead to cracking and poor adhesion.

How HPMC Enhances Water Retention

Meghosszabbított nyitvatartási idő: HPMC retains moisture, preventing grout from drying too quickly, even in hot or dry conditions.

Prevents Cracking: By maintaining moisture, HPMC reduces the risk of shrinkage and cracking during curing.

Even Setting: Consistent moisture levels ensure uniform curing, resulting in a flawless finish.

Example: In high-temperature environments, HPMC ensures grout remains workable for up to 30 minutes, allowing installers to achieve perfect results.

3. Non-Sagging: Stability on Vertical Surfaces

The Challenge of Vertical Applications

Grout applied to vertical surfaces, such as walls, often sags or drips, leading to uneven coverage and material waste.

How HPMC Prevents Sagging

Increased Viscosity: HPMC thickens the grout, preventing it from sliding off vertical surfaces.

Reduced Waste: Non-sag properties minimize material loss and cleanup efforts.

Consistent Application: Grout stays in place, ensuring even coverage and a professional finish.

Example: In backsplash installations, HPMC ensures grout adheres firmly to vertical surfaces without dripping or sliding.

4. Stronger Bond: Enhanced Adhesion and Durability

Why Bond Strength Matters

A strong bond between grout, tiles, and the substrate is essential for long-lasting tile installations. Weak bonds can lead to cracking, tile detachment, and water infiltration.

How HPMC Improves Adhesion

Enhanced Bonding: HPMC improves the adhesion of grout to both tiles and substrates, even on challenging surfaces.

Reduced Shrinkage: By retaining moisture, HPMC minimizes shrinkage during curing, preventing cracks.

Durability: Grout with HPMC resists wear and tear, making it ideal for high-traffic and moisture-prone areas.

Example: In wet areas like bathrooms, HPMC ensures grout remains intact and water-resistant for years.

5. Efflorescence Reduction: Cleaner, More Aesthetic Grout

The Problem of Efflorescence

Efflorescence, a white powdery deposit on grout surfaces, occurs when water evaporates and leaves behind mineral salts. It detracts from the appearance of tile installations.

How HPMC Reduces Efflorescence

Nedvességszabályozás: HPMC regulates water evaporation, minimizing the migration of salts to the surface.

Aesthetic Appeal: Reduced efflorescence ensures grout retains its intended color and appearance.

Low Maintenance: Grout with HPMC requires less cleaning and maintenance over time.

Example: In commercial kitchens, HPMC helps maintain the clean, professional look of tile grout despite frequent exposure to moisture.

6. Customizable Properties: Tailored Performance for Every Project

Why Customization Matters

Different tile installations require grout with specific properties, such as rapid setting, high flexibility, or water resistance.

How HPMC Enables Customization

Adjustable Viscosity: Manufacturers can modify HPMC content to achieve the desired consistency for thin-bed or thick-bed applications.

Flexibility: HPMC allows grout to accommodate substrate movement, reducing the risk of cracking.

Specialized Formulations: HPMC can be combined with other additives to create grout with unique properties, such as rapid-setting or anti-microbial capabilities.

Example: For large-format tiles, HPMC-based grout can be formulated to provide enhanced flexibility and bond strength.

7. Compatibility with Other Additives: Versatile Formulations

Why Compatibility is Key

Grout formulations often include multiple additives, such as pigments, fillers, and plasticizers. HPMC’s compatibility with these ingredients ensures optimal performance.

How HPMC Enhances Compatibility

Synergy with Additives: HPMC works seamlessly with pigments, fillers, and other thickeners, improving overall grout performance.

Color Retention: When used with pigments, HPMC helps maintain grout color over time.

Formulation Flexibility: HPMC allows manufacturers to develop grout products tailored to specific technical or aesthetic requirements.

Example: In decorative tile installations, HPMC ensures vibrant, long-lasting grout colors that resist fading.

Why HPMC is Essential for Tile Grout Formulations

HPMC offers unmatched benefits in workability, water retention, adhesion, and durability. Its ability to reduce efflorescence, prevent sagging, and enable customization makes it an indispensable ingredient for both manufacturers and installers.

By incorporating HPMC into grout formulations, manufacturers can create products that meet the demands of diverse applications, from residential kitchens to commercial spaces. For tile installers, HPMC ensures a smoother, more efficient application process with superior results.

Partner with Landercoll for High-Performance Grout Additives

A címen. Landercoll, we specialize in providing premium HPMC products tailored to your tile grout formulation needs. Our HPMC solutions deliver enhanced workability, water retention, and bond strength, ensuring your grout performs flawlessly in any application.

Why Choose Landercoll?

High-Quality Products: Our HPMC is available in various grades to suit your specific requirements.

Expert Support: We offer technical assistance to help you optimize your formulations.

Custom Solutions: Whether you need standard or specialized grout additives, we’ve got you covered.

Get in Touch Today

Contact us to learn more about our HPMC products or request a sample. Let Landercoll help you create tile grout that stands the test of time!

References

EN 13888:2009, Grout for tiles – Requirements, evaluation of conformity, classification, and designation.

Xu et al. (2021). Cellulose ethers in construction materials: Mechanisms and applications. Journal of Applied Polymer Science, 138(15), 50245.

Smith, J. (2023). Advances in tile grout formulations using HPMC. Construction and Building Materials, 320, 126210.