In SCIP panel construction, achieving optimal concrete performance requires advanced additives like Hydroxypropyl Methyl Cellulose(HPMC) and polycarboxylate superplasticizer. HPMC enhances water retention, ensuring consistent hydration and reducing shrinkage. Meanwhile, polycarboxylate superplasticizer improves fluidity by lowering the water-to-cement ratio, which helps you create denser, more durable concrete. These innovations not only improve strength but also address challenges like cracks and permeability.

- Cost efficiency: Reduced maintenance needs.

- Improved workability: Easier handling in complex projects.

- Enhanced strength: Higher compressive resistance.

- Durability: Extended lifespan through crack prevention.

These additives redefine modern construction by combining efficiency with long-term performance.

Key Takeaways

- HPMC helps concrete hold water, keeping it strong and lasting longer.

- Polycarboxylate superplasticizer makes concrete flow better for easy pouring.

- These additives lower the chance of cracks and make SCIP panels last longer.

- Mixing HPMC and polycarboxylate superplasticizer creates tougher and better concrete.

- Using the right amounts and mixing properly is key for good SCIP panels.

1. Properties of HPMC and Polycarboxylate Superplasticizer

1.1 HPMC: A Key Additive

Chemical structure and composition

Hydroxypropyl Methylcellulose (HPMC) is a cellulose-derived polymer that plays a critical role in modern concrete formulations. Its chemical structure includes hydroxyl groups that enhance water retention and methyl groups that improve thermal stability. This unique composition makes HPMC an eco-friendly and biodegradable additive, aligning with sustainable construction practices.

Properties that enhance concrete performance

HPMC offers several benefits that directly impact the quality of SCIP panels:

- Water Retention: It prevents rapid evaporation, ensuring proper curing and improving strength.

- Durability: It enhances resistance to cracking, shrinkage, and environmental stresses, extending the lifespan of structures.

- Improved Adhesion: It strengthens bonding with substrates, making it ideal for overlays and repairs.

- Thermal Stability: It reduces the risk of thermal cracking by improving resistance to temperature fluctuations.

- Mixture Homogeneity: It maintains uniform material distribution, ensuring consistent quality.

Property/Benefit | Description |

Water Retention | Prevents rapid evaporation, ensuring proper curing and improving strength and durability. |

Durability | Increases resistance to cracking, shrinkage, and environmental stresses, extending service life. |

Adhesive Properties | Enhances bonding with substrates, beneficial for overlays and repairs. |

Mixture Homogeneity | Maintains uniform distribution of materials, preventing delamination and ensuring quality. |

Thermal Stability | Improves resistance to temperature fluctuations, reducing thermal cracking risk. |

1.2 Polycarboxylate Superplasticizer: The Fluidity Booster

Mechanism of action in concrete mixes

Polycarboxylate superplasticizers (PCEs) work by dispersing cement particles in the mixture. Their long molecular chains create an electrostatic repulsion effect, which reduces water demand while maintaining workability. This mechanism allows you to achieve a more fluid and cohesive mix without compromising strength.

Key benefits for SCIP panels

Polycarboxylate superplasticizers (PCEs) offer transformative advantages for SCIP panel construction:

- Water Reduction: They significantly lower water content, resulting in denser and more durable concrete.

- Workability Retention: They maintain fluidity over extended periods, ideal for large-scale or complex projects.

- Cost Efficiency: While they increase upfront costs, they reduce long-term maintenance expenses by enhancing durability.

Why These Additives Are Essential for SCIP Panels

Addressing common challenges in SCIP panel construction

SCIP panels often face issues like cracking, shrinkage, and inconsistent quality. HPMC and Polycarboxylate superplasticizers (PCEs) address these challenges by improving water retention, reducing segregation, and enhancing fluidity. These additives ensure that your panels meet the highest performance standards.

Enhancing performance metrics

By incorporating HPMC and Polycarboxylate superplasticizers (PCEs), you can improve strength, durability, and workability in SCIP panels. These additives also enhance thermal stability and environmental resistance, making them indispensable for modern construction projects. Whether you’re working on high-rise structures or large-scale infrastructure, these materials ensure consistent and reliable results.

2. How HPMC Helps Improve Strength and Fluidity

Enhancing Workability

Water retention and consistency benefits

Hydroxypropyl Methyl Cellulose(HPMC) significantly enhances the workability of concrete by improving its water retention properties. It prevents rapid water evaporation, ensuring that the cement particles remain hydrated throughout the curing process. This consistent hydration leads to a smoother, more cohesive mix, making it easier for you to handle and shape the concrete. Additionally, HPMC stabilizes the mixture, reducing segregation and maintaining uniformity in the material distribution. These benefits directly contribute to better performance and durability in SCIP panels.

Application in SCIP panel construction

In SCIP panel construction, achieving a balance between strength and fluidity is critical. HPMC ensures that the concrete mix remains workable for extended periods, even in challenging conditions. This allows you to pour and shape the panels with precision, minimizing errors and defects. Its ability to maintain consistency also reduces the likelihood of cracks or weak spots, ensuring that the panels meet high-performance standards.

Strengthening Concrete

Reducing cracks and shrinkage

HPMC plays a vital role in reducing cracks and shrinkage in concrete. By retaining water within the mix, it prevents premature drying, which is a common cause of shrinkage. This controlled curing process minimizes internal stresses, reducing the risk of cracks forming over time. As a result, you can rely on HPMC to produce concrete that is both durable and visually flawless.

Long-term durability improvements

The long-term durability of concrete is another area where HPMC excels. Its ability to enhance water retention and reduce shrinkage directly contributes to the structural integrity of SCIP panels. Over time, this translates into fewer maintenance requirements and a longer lifespan for your projects. HPMC also improves resistance to environmental factors like temperature fluctuations and moisture, ensuring that the panels remain strong and stable under various conditions.

Additional Advantages of HPMC

Environmental resistance

HPMC enhances the environmental resistance of concrete, making it suitable for use in harsh climates. It improves the material’s ability to withstand temperature changes, moisture, and chemical exposure. This ensures that your SCIP panels maintain their structural integrity and appearance over time, even in demanding environments.

Compatibility with other additives

One of the standout features of HPMC is its compatibility with other concrete additives, such as polycarboxylate superplasticizers. This compatibility allows you to combine the benefits of multiple additives, achieving a mix that is both strong and fluid. The table below highlights some of the key features and benefits of HPMC:

Feature | Benefit |

Water Retention | Prevents rapid evaporation, ensuring proper curing and improving strength. |

Durability | Increases resistance to cracking, shrinkage, and environmental stresses. |

Adhesion | Enhances bonding with substrates, beneficial for overlays and repairs. |

Eco-friendliness | Contributes to sustainable construction practices. |

By leveraging these advantages, you can optimize the performance of your SCIP panels while adhering to sustainable construction practices.

3. How Polycarboxylate Superplasticizer Improves Strength and Fluidity

Boosting Fluidity

Water reduction mechanism

Polycarboxylate superplasticizer (PCE) enhances fluidity by reducing the water-to-cement ratio in concrete mixes. Its long molecular chains create an electrostatic repulsion among cement particles, dispersing them evenly throughout the mixture. This mechanism minimizes water demand while maintaining workability. By using PCE, you can achieve a more cohesive and fluid mix without compromising the structural integrity of the concrete.

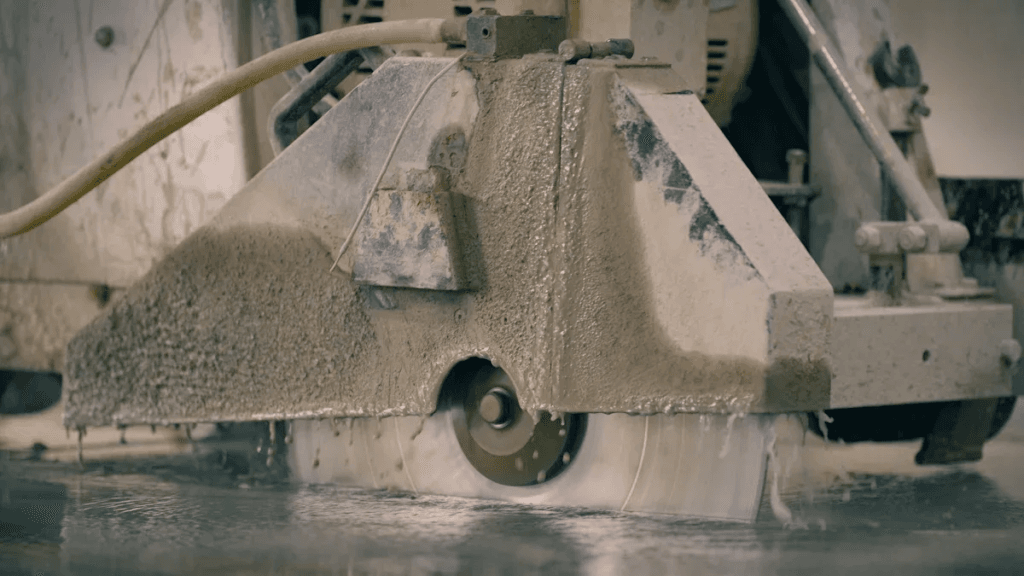

Benefits for pouring and setting in SCIP panels

The improved fluidity provided by PCE offers significant advantages during SCIP panel construction. It ensures that the concrete flows smoothly into molds, filling every corner and crevice without leaving voids. This property is especially beneficial for intricate designs or large-scale projects where precision is critical. Additionally, the enhanced workability allows for faster and more efficient pouring, reducing labor time and ensuring consistent quality across all panels.

Enhancing Strength

Increased density and load-bearing capacity

PCE contributes to denser concrete by reducing the amount of water in the mix. This increased density directly translates to higher load-bearing capacity, making your SCIP panels more robust and capable of withstanding greater stress. The improved density also enhances resistance to wear and tear, ensuring long-term durability.

Reduction of voids and air pockets

By dispersing cement particles uniformly, PCE minimizes the formation of voids and air pockets within the concrete. These imperfections can weaken the structure and reduce its lifespan. With PCE, you can produce concrete that is not only stronger but also more reliable, meeting the highest performance standards.

Other Benefits of Polycarboxylate Superplasticizer

Faster curing times

PCE accelerates the curing process by optimizing water retention and maintaining consistency in the mix. This faster curing time allows you to complete projects more quickly without sacrificing quality.

- PCE enhances water reduction and workability retentioncompared to traditional superplasticizers.

- It maintains performance over time, contributing to quicker curing and improved efficiency.

Improved surface finish

The use of PCE results in a smoother and more uniform surface finish. This aesthetic improvement reduces the need for additional finishing work, saving time and resources. Whether you’re constructing residential or commercial buildings, the enhanced surface quality adds value to your projects.

4. Synergistic Effects of HPMC and Polycarboxylate Superplasticizer

Complementary Mechanisms

Balancing fluidity and cohesion

HPMC and polycarboxylate superplasticizer work together to balance fluidity and cohesion in concrete mixes. While HPMC enhances water retention and stabilizes the mixture, polycarboxylate superplasticizer reduces water demand and improves flowability. This combination ensures that the concrete remains workable without compromising its structural integrity. You can achieve a mix that is easy to pour and shape while maintaining the strength required for SCIP panels. This balance is critical for projects where precision and durability are essential.

Enhanced performance in SCIP panels

When used together, these additives significantly enhance the performance of SCIP panels. HPMC minimizes shrinkage and cracking, while polycarboxylate superplasticizer ensures uniform material distribution. This synergy results in panels with improved strength, durability, and resistance to environmental stresses. By leveraging these complementary properties, you can produce SCIP panels that meet the highest industry standards.

Real-World Applications

Case studies in SCIP panel projects

In real-world applications, the combination of HPMC and polycarboxylate superplasticizer has delivered remarkable results. For instance, in a high-rise construction project, these additives improved the fluidity of the concrete mix, allowing for faster pouring and reduced labor costs. The panels exhibited enhanced durability and resistance to cracking, even under extreme weather conditions. These case studies highlight the practical benefits of using these additives in SCIP panel construction.

Measurable improvements in strength and fluidity

The synergy between HPMC and polycarboxylate superplasticizer leads to measurable improvements in both strength and fluidity. Tests have shown that concrete mixes incorporating these additives achieve higher compressive strength and better workability compared to traditional mixes. This makes them ideal for complex projects where performance and efficiency are critical.

Addressing Challenges

Compatibility considerations

When combining HPMC and polycarboxylate superplasticizer, you must ensure their compatibility to avoid adverse reactions. Both additives should be tested in small batches to confirm that they work well together. This step is crucial for maintaining the quality and consistency of your concrete mix.

Optimal mixing ratios

Determining the optimal mixing ratios is another challenge you may face. The effectiveness of these additives depends on precise dosages tailored to your specific project requirements. Consulting with experts or referring to manufacturer guidelines, such as those for Landercoll HPMC and NOVASTAR Polycarboxylate Superplasticizer, can help you achieve the best results.

5. Practical Applications and Best Practices

Guidelines for Effective Use

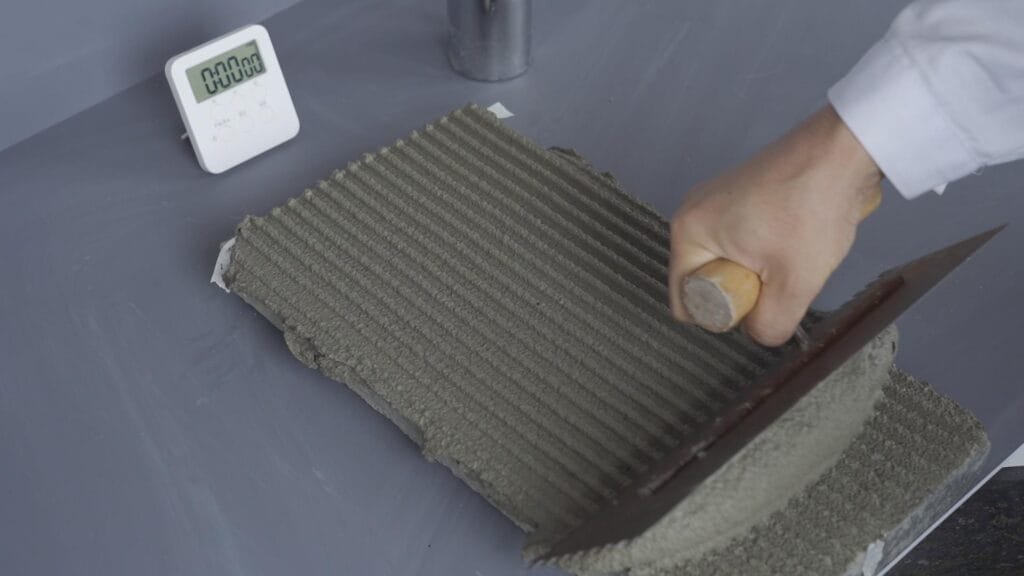

Recommended dosages and mixing techniques

To achieve optimal results with HPMC and polycarboxylate superplasticizer, precise dosages and mixing techniques are essential. For HPMC, you should typically use 0.1% to 0.5% of the total cement weight, depending on the desired water retention and consistency. Polycarboxylate superplasticizer, such as NOVASTAR, requires a dosage of 0.2% to 0.8% of the cement weight to maximize fluidity and strength. Always follow manufacturer guidelines to tailor these ratios to your specific project needs.

When mixing, ensure that HPMC is thoroughly dispersed in water before adding it to the cement mix. This step prevents clumping and ensures uniform distribution. For polycarboxylate superplasticizer, add it after the initial mixing phase to achieve the best dispersion of cement particles. Using a high-shear mixer can further enhance the homogeneity of the blend, ensuring consistent quality in SCIP panels.

Ensuring uniform distribution in SCIP panels

Uniform distribution of additives is critical for the performance of SCIP panels. Uneven mixing can lead to weak spots, cracks, or inconsistent fluidity. To avoid this, you should use automated batching systems or carefully calibrated manual methods. Tools like vibrating tables can help eliminate air pockets and ensure even material flow during panel casting. By following these practices, you can produce panels with superior strength and durability.

Quality Control in SCIP Panel Construction

Monitoring additive performance

Regular monitoring of additive performance is vital to maintaining the quality of SCIP panels. Conduct slump tests to evaluate workability and ensure that the mix meets project specifications. Compressive strength tests can verify the structural integrity of the panels. For additives like Landercoll HPMC and NOVASTAR Polycarboxylate Superplasticizer, periodic quality checks ensure that they perform as intended, delivering consistent results across batches.

Avoiding common pitfalls

Common pitfalls in SCIP panel construction include over-dosing or under-dosing additives, which can compromise the mix’s properties. To avoid this, always measure additives accurately and adhere to recommended dosages. Another issue is improper mixing, which can lead to segregation or uneven curing. Using the right equipment and following best practices can help you avoid these challenges, ensuring high-quality panels every time.

Future Trends in Concrete Additives

Innovations in HPMC and superplasticizers

The future of concrete additives is marked by exciting innovations. Superplasticizers like Polycarboxylate Ether (PCE) are becoming more efficient and versatile, enhancing workability and strength for large-scale projects. New additives with advanced functionalities, such as corrosion resistance and self-healing properties, are also emerging. Technological advancements, including AI and machine learning, are optimizing the manufacturing processes of additives like Landercoll HPMC and NOVASTAR, making them more effective and sustainable.

- Enhanced functionalities like self-healing and corrosion resistance.

- AI-driven optimization of additive manufacturing.

- Increased versatility for large-scale applications.

Sustainability and eco-friendly practices

Sustainability is a driving force in the development of concrete additives. The global cement additive market is projected to grow significantly, reaching $10.25 billion by 2034. This growth reflects the rising demand for eco-friendly solutions in construction. Additives like Landercoll HPMC and NOVASTAR Polycarboxylate Superplasticizer align with green building practices by reducing water usage and enhancing durability, minimizing the environmental impact of construction projects.

- Stringent regulations promote sustainable construction methods.

- Green building practices drive demand for eco-friendly additives.

- Technological advancements support the development of innovative, sustainable solutions.

By staying informed about these trends, you can adopt cutting-edge practices that enhance both performance and sustainability in SCIP panel construction.

The use of HPMC and polycarboxylate superplasticizer in SCIP panels has revolutionized concrete applications in modern construction. These additives enable you to achieve precision in complex and large-scale projects while improving workability, strength, and long-term durability.

- Key Benefits:

- Improved workabilityfor easier handling.

- Enhanced strength and crack resistance.

- Long-term durability under various environmental conditions.

Benefit | Description |

Biodegradable | HPMC, derived from natural cellulose, is biodegradable and non-toxic. |

Eco-friendly | Supports environmentally sustainable construction practices. |

Reduced Impact | Minimizes the environmental footprint of construction activities. |

By incorporating Landercoll HPMC and NOVASTAR Polycarboxylate Superplasticizer, you contribute to sustainable construction practices while ensuring superior performance in SCIP panels. These innovations not only enhance construction quality but also align with the growing demand for eco-friendly solutions.

5. Frequently Asked Questions

What makes Landercoll HPMC unique for SCIP panels?

Landercoll HPMC offers superior water retention and consistency, ensuring optimal curing and reduced shrinkage. Its eco-friendly, biodegradable composition aligns with sustainable construction practices. You can rely on it for enhanced durability and crack resistance in SCIP panels.

How does NOVASTAR Polycarboxylate Superplasticizer improve concrete fluidity?

NOVASTAR reduces water demand while maintaining workability. Its advanced molecular structure disperses cement particles evenly, creating a cohesive and fluid mix. This ensures smooth pouring and precise shaping, especially for intricate SCIP panel designs.

Can I use Landercoll HPMC and NOVASTAR together?

Yes, they complement each other perfectly. Landercoll stabilizes the mix, while NOVASTAR enhances fluidity. Together, they create a balanced concrete mix with improved strength, durability, and workability, ideal for SCIP panel construction.

What are the recommended dosages for these additives?

For Landercoll HPMC, use 0.1%–0.5% of the cement weight. For NOVASTAR Polycarboxylate Superplasticizer, apply 0.2%–0.8%. Always follow manufacturer guidelines and test small batches to determine the optimal ratio for your project.

Are these additives suitable for eco-friendly construction?

Absolutely! Both Landercoll HPMC and NOVASTAR Polycarboxylate Superplasticizer reduce water usage and enhance durability, minimizing environmental impact. Their use supports sustainable construction practices and aligns with green building standards.