1. Understanding Pre-Mixed Dry Mortar

Pre-mixed dry mortar is a high-quality mixture of cement, sand, and additives, produced in a controlled environment to deliver consistent results. Unlike traditional mortar, PMDM reduces the occurrence of common problems such as cracking, hollowing, and shelling. However, to achieve these benefits, it requires specific handling and application techniques. When traditional methods are applied without proper adjustments, several quality issues can arise.

These issues often stem from improper material handling, poor mixing, and inadequate curing techniques. Furthermore, the variability in the quality standards of manufacturers and the lack of awareness among contractors about the material’s behavior and best practices contribute to these challenges.

2. Common Quality Issues and Preventive Measures

2.1 Plastic Shrinkage Cracking

Cause: Plastic shrinkage cracking occurs during the early stages of the mortar setting when rapid moisture loss leads to shrinkage stress. Common causes include:

- High cement content

- Low sand fineness modulus

- High water-to-cement ratio

- Environmental factors like high temperature, wind, and low humidity

Preventive Measures:

- Reduce cement content and optimize the sand fineness modulus to improve mix consistency.

- Incorporate appropriate retarders and additives to slow down moisture evaporation.

- Monitor environmental conditions and take steps to control temperature and humidity during construction.

2.2 Drying Shrinkage Cracking

Cause: Drying shrinkage cracking happens after the mortar sets, primarily due to moisture loss and the associated volume shrinkage. Contributing factors include:

- High cement content

- Inadequate curing methods

- Mismatched elastic modulus between mortar and substrate materials

Preventive Measures:

- Use low-shrinkage additives and reduce cement content to minimize shrinkage.

- Implement proper curing techniques to maintain moisture levels during hydration.

- Ensure compatibility between the mortar and substrate materials to reduce the risk of cracking.

2.3 Clumping and Aggregation

Cause: Clumping of mortar results in reduced performance and inconsistent quality. Causes include:

- Insufficient drying of sand

- Short or uneven mixing times

- Variations in the quality of raw materials from production companies

- Lack of maintenance of mixing equipment

Preventive Measures:

- Enforce stringent quality control measures at production facilities to ensure consistency.

- Clean and maintain mixing equipment regularly to ensure thorough blending.

- Provide contractors with adequate training on proper material handling and mixing practices.

2.4 Non-Compliance with Test Block Strength

Cause: Inconsistent test block strength can indicate poor-quality mortar, often due to:

- Use of unqualified molds

- Improper curing and preparation of test blocks

- Non-standard testing methods

Preventive Measures:

- Train staff on proper testing and curing procedures.

- Ensure test molds meet industry standards.

- Regularly inspect and calibrate testing equipment to ensure accurate measurements.

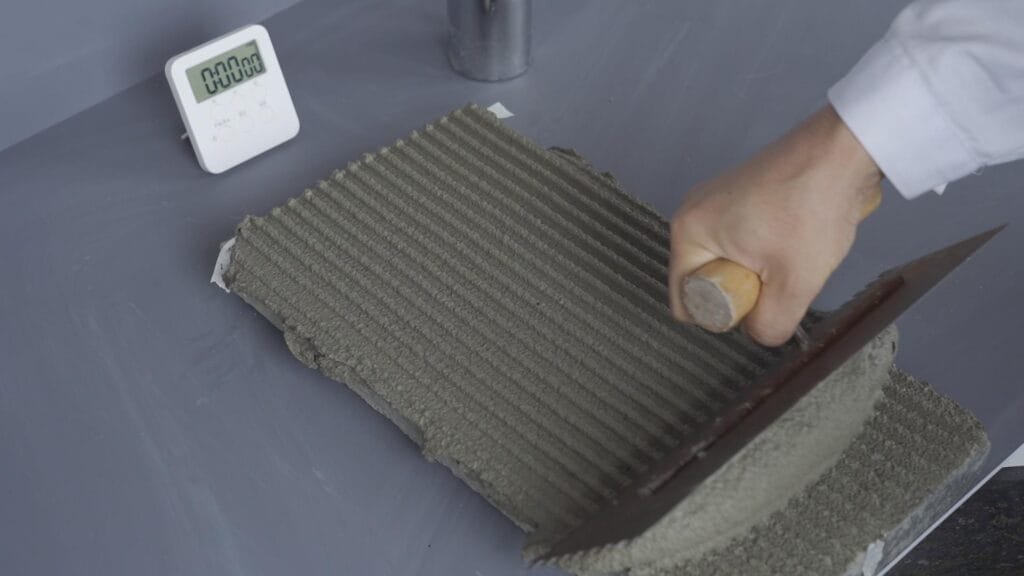

2.5 Surface Detachment and Uneven Finish

Cause: Poor surface adhesion, which leads to peeling or sand shedding, is a frequent issue. Causes include:

- Excessively fine sand with high clay content

- Insufficient bonding agent content

Preventive Measures:

- Control the particle size distribution of sand, ensuring low clay content.

- Increase the proportion of cementitious materials and bonding agents to improve adhesion.

2.6 Inconsistent Setting Time

Cause: Variability in setting time can disrupt the construction workflow and schedule. Contributing factors include:

- Temperature variations

- Excessive moisture content

- Improper use of retarders

Preventive Measures:

- Adjust formulations based on environmental conditions and project-specific requirements.

- Monitor site conditions and control the use of retarders to maintain consistent setting times.

2.7 Water Separation and Surface Foaming

Cause: Water separation and foaming can occur due to poor mixing or excessive water content. Causes include:

- Inadequate mixing times

- Insufficient use of water retention agents

- Poor sand grading

Preventive Measures:

- Improve mixing time and ensure thorough integration of materials.

- Optimize sand grading and use sufficient water retention agents to prevent separation and foaming.

3. Best Practices for Preventing Quality Issues in Pre-Mixed Dry Mortar

Ensuring the quality of pre-mixed dry mortar involves understanding its behavior, optimizing its composition, and adhering to best construction practices. Here are some critical measures to minimize quality issues:

- Manufacturer Specifications:Always follow the manufacturer’s guidelines on mortar composition, mix ratios, and application procedures to ensure consistency.

- Proper Curing:Proper curing of mortar is essential for maintaining hydration and preventing cracking. Implementing standard curing practices ensures better long-term performance.

- Environmental Control:Monitor environmental factors such as temperature, humidity, and wind, and adjust construction practices to optimize the setting and curing conditions.

- Continuous Training:Educate contractors and site workers on the proper handling, mixing, and application techniques to avoid mistakes that lead to quality problems.

- Regular Quality Control:Implement strict quality control measures at both the production and construction stages, including regular inspections, testing, and maintenance of equipment.

4. Ensuring High-Quality Pre-Mixed Dry Mortar for Superior Construction

While pre-mixed dry mortar offers many benefits, such as improved efficiency, higher quality, and sustainability, quality issues can still arise if not handled properly. By understanding the causes of common problems like plastic shrinkage cracking, clumping, and inconsistent setting times, contractors and manufacturers can take proactive measures to minimize defects.

For optimal results, ensure that pre-mixed dry mortar is used according to industry standards and manufacturer specifications. Continuous training, quality control, and environmental monitoring are key to maintaining mortar performance and achieving successful outcomes in construction projects.

By adopting these best practices, the construction industry can continue to benefit from the efficiency, cost-effectiveness, and eco-friendly advantages of pre-mixed dry mortar while minimizing the risk of quality issues.